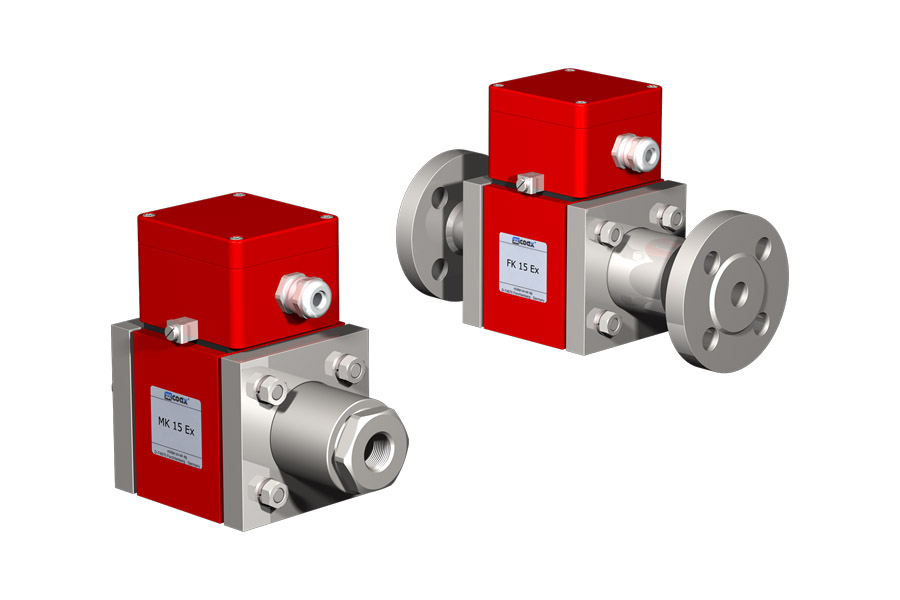

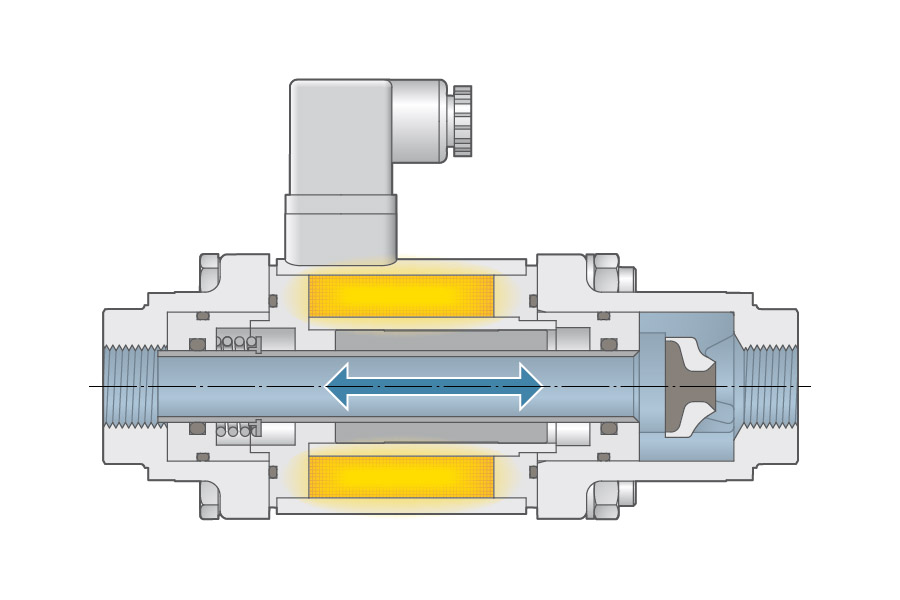

The chemical industry satisfies the needs for raw materials for critical industry segments. müller co-ax provides valves with the highest degree of process reliability in corrosive or explosive environments, for the handling of industrial gases or process engineering systems for the production of plastics. Acids, alkalies, gases as well as high-viscosity media can be controlled due to application-related selections to housing materials as well as the interior parts and seals that come into contact with the media.