At co-ax valves inc., we’re excited to share the KX 1000 high-pressure valve, designed specifically for the evolving world of hydrogen technology. As we push towards a future fueled by renewable energy, the need for reliable, advanced components in hydrogen applications has never been greater. The KX 1000 is here to meet those needs with unmatched performance and innovation.

The KX 1000 is designed to handle hydrogen pressures up to 14,500 PSI. This makes it perfect for demanding environments like hydrogen filling and storage systems. If you’re dealing with high-pressure or need precise control, this valve is up to the task.

Time is money, especially in hydrogen refueling and handling. The KX 1000’s large nominal diameter speeds up the filling and evacuation processes, resulting in quicker turnaround times and increased efficiency. This is crucial when it comes to scaling up hydrogen refueling stations to meet growing demand.

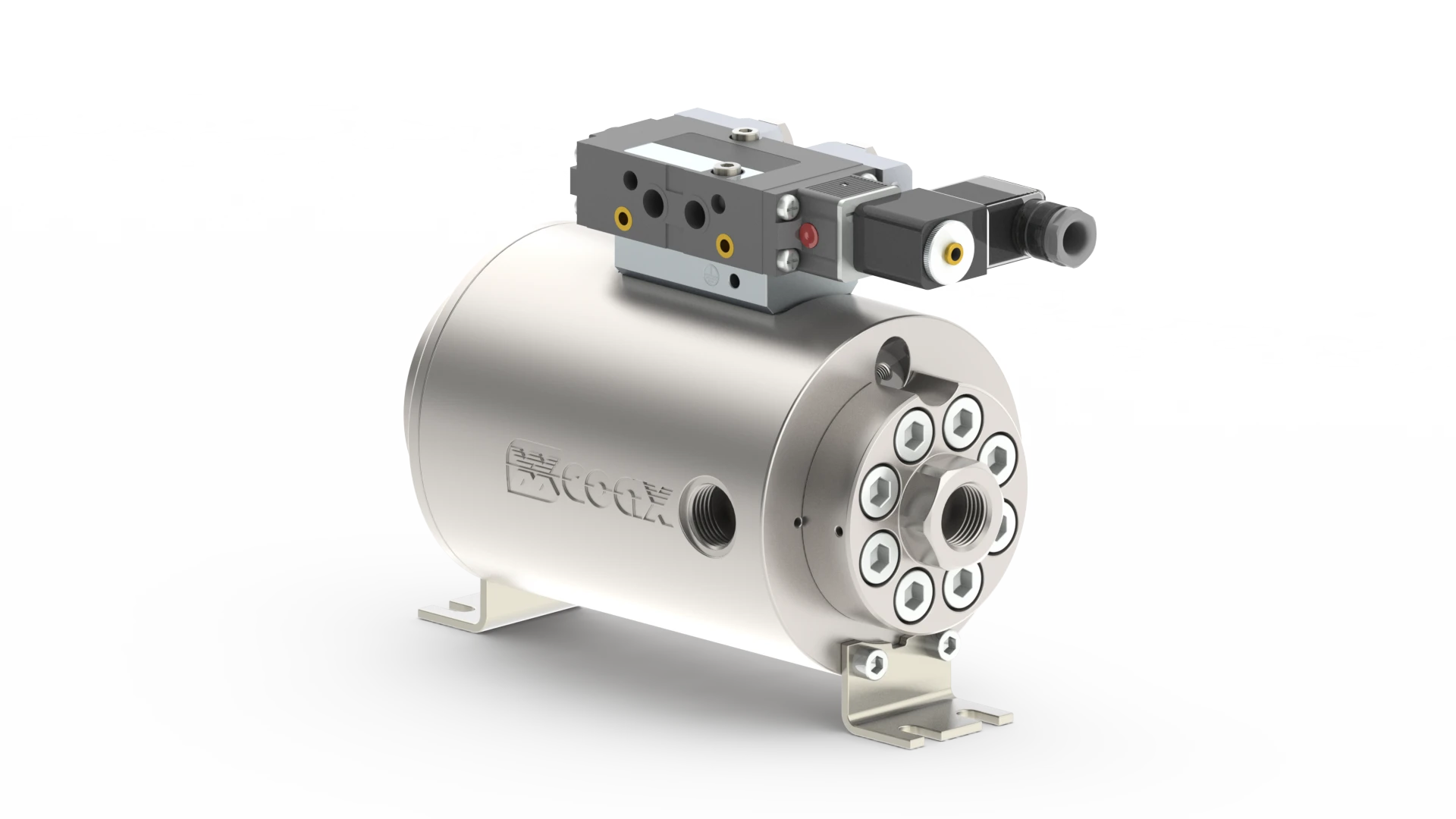

Space is often at a consideration in industrial setups. The KX 1000’s compact design allows it to fit into tight spaces without sacrificing performance. It’s built to deliver robust results, making it a versatile choice for various applications.

The reliable operation of the on/off control valves is critical to the safety and stability of the entire system. Given the flammability and explosive nature of hydrogen, the KX 1000 valve utilizes pneumatic actuation to achieve programmed, automatic, and remote leak-tight control of the valve. Due to the integral, low-profile actuator, the instrument air consumption is significantly reduced.

The KX 1000 isn’t just another valve. Its pressure-balanced design maximizes flow while maintaining a low profile. Adjustable speed controls allow for exact timing of the opening and closing speed. Inductive limit switches for precisely monitoring the open/close position are optional.

When stacked up against competitors, the KX 1000 excels with its superior pressure handling, compact size, and efficiency. While other valves might struggle with space or high instrument air consumption, the KX 1000 handles these challenges with ease.

The hydrogen industry is experiencing rapid growth as global efforts to transition to renewable energy sources intensify. The demand for advanced components like the KX 1000 is rising, driven by the need for efficient, reliable solutions in hydrogen production, storage, and refueling.

The KX 1000 meets strict industry regulations and standards, including those for high-pressure and hazardous locations, ensuring it’s safe and reliable for all applications.

We’re always working on new technologies to enhance our products used in hydrogen applications. Stay tuned for future products and advancements that will continue to push the boundaries of what’s possible.

Our dedication to sustainability goes beyond the KX 1000. We’re committed to developing eco-friendly products and supporting initiatives for a cleaner, greener future.

Want to learn more about the KX 1000? Reach out to us for more details or to request a quote. Our experienced team will be more than happy to help you to integrate this cutting-edge valve into your systems.